Crumbler® Rotary Shear

Save Costs and Improve Feedstock Quality

Size reduction is a key processing step for feedstocks. Traditional methods include hammermills, grinders, and chippers. However, these methods typically are either limited to producing ½” and larger particles or require pre-drying of biomass at a substantial energy cost. Additionally, these methods may produce large amounts of fines with wide particle distributions and poor flowability.

Forest Concepts developed the Crumbler® rotary shear to address these common problems and produce a superior result.

Key Benefits:

- Processes any moisture content – no pre-drying necessary

- Scalable for both small & industrial-scale operations

- Tested on many materials – wood, recyclables, corn stover, hemp & more (see the complete list)

- Results in evenly shaped highly-flowable particles with less fines

- Efficiently produces particles as small as 1mm

- Quiet performance – our in-house experience demonstrates that Crumbler® operates at 85 db versus traditional hammermill at 110-120 db

- Low carbon footprint (learn more)

- 100% manufactured in the USA

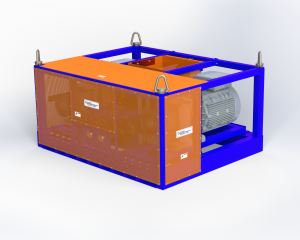

P24 Family Machines

Industrial, pilot-scale rotary shear.

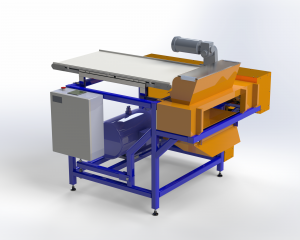

M24M Family Machines

Small scale industrial rotary shear.

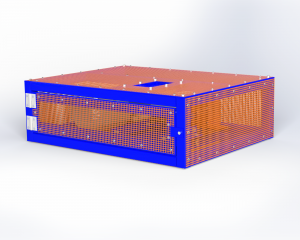

M24P Family Machines

Pilot-scale commercial rotary shear.

M24S Family Machines

Small-scale industrial ChipMuncher™ rotary shear.

M8M Family Machines

Research and lab rotary shear.

M8L Family Machines

Rotary shear system for lab and research use.

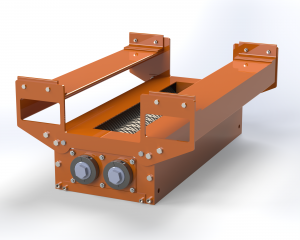

Crumbler® Processing Heads

Designed for optimal particle size reduction. Required for all Crumbler® rotary shear machines.

Related Items to Consider

Read more about our Crumbler® technology:

Flowability of Crumbler Rotary Shear Size-Reduced Granular Biomass: An Experiment-Informed Modeling Study on the Angle of Repose

Abstract Biomass has potential as a carbon-neutral alternative to petroleum for chemical and energy products. However, complete replacement of fossil fuel is contingent upon efficient processes to eliminate undesirable characteristics of biomass, e.g., low bulk density, variability, and storage-induced quality

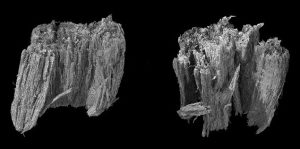

Measurement of Transport Properties of Woody Biomass Feedstock Particles Before and After Pyrolysis by Numerical Analysis of X-Ray Tomographic Reconstructions

Abstract Lignocellulosic biomass has a complex, species-specific microstructure that governs heat and mass transport during conversion processes. A quantitative understanding of the evolution of pore size and structure is critical to optimize conversion processes for biofuel and bio-based chemical production.

Investigation of Cutter-Woodchip Contact Pressure in a New Biomass Comminution System

Abstract A Crumbler® rotary shear system was recently developed to process fuel-grade woodchips into feedstocks having more uniform particle sizes for improved flowability and higher thermochemical output yield than a traditional hammer mill. It represents a significant innovation in the

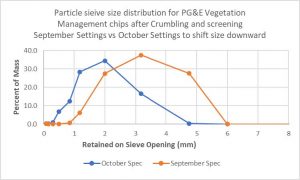

Processing Powerline Vegetation Management Biomass for Use in Distributed-Scale Gasifiers

Pacific Gas and Electric (PG&E) sponsored a project to explore methods to gather powerline vegetation management woody biomass and process it into feedstocks optimized for delivery to distributed-scale gasifiers. A pilot study was conducted in Lake County, California where powerline trimmings were either chipped or baled, then ground at a central biomass processing facility, and finally milled / screened to achieve particle size distributions specified by a gasifier manufacturer. The vegetation included oak, pine, walnut, and other hardwoods. All materials were successfully processed into feedstocks.

Forest Concepts M24M Modular Tower Crumbler® System Installed at Idaho National Lab User Facility

Idaho National Lab is undergoing a $15 million upgrade to the Process Development Unit (PDU) and Biomass Feedstocks National User Facility in Idaho Falls, Idaho. Researchers at the lab can assist with analytics, supply/logistics issues, and characterization to help industry players scale

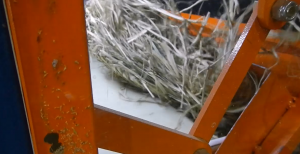

Crumbling and Screening Switchgrass

Forest Concepts’ custom processing equipment size reducing and screening of switchgrass materials.