Crumbler® Rotary Shear

Save Costs and Improve Feedstock Quality

Size reduction is a key processing step for feedstocks. Traditional methods include hammermills, grinders, and chippers. However, these methods typically are either limited to producing ½” and larger particles or require pre-drying of biomass at a substantial energy cost. Additionally, these methods may produce large amounts of fines with wide particle distributions and poor flowability.

Forest Concepts developed the Crumbler® rotary shear to address these common problems and produce a superior result.

Key Benefits:

- Processes any moisture content – no pre-drying necessary

- Scalable for both small & industrial-scale operations

- Tested on many materials – wood, recyclables, corn stover, hemp & more (see the complete list)

- Results in evenly shaped highly-flowable particles with less fines

- Efficiently produces particles as small as 1mm

- Quiet performance – our in-house experience demonstrates that Crumbler® operates at 85 db versus traditional hammermill at 110-120 db

- Low carbon footprint (learn more)

- 100% manufactured in the USA

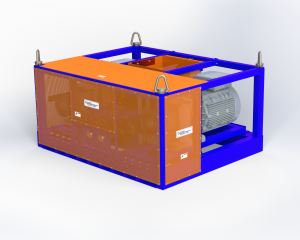

P24 Family Machines

Industrial, pilot-scale rotary shear.

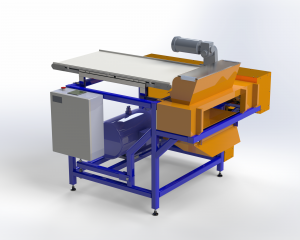

M24M Family Machines

Small scale industrial rotary shear.

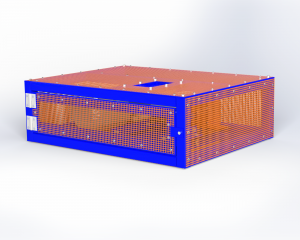

M24P Family Machines

Pilot-scale commercial rotary shear.

M24S Family Machines

Small-scale industrial ChipMuncher™ rotary shear.

M8M Family Machines

Research and lab rotary shear.

M8L Family Machines

Rotary shear system for lab and research use.

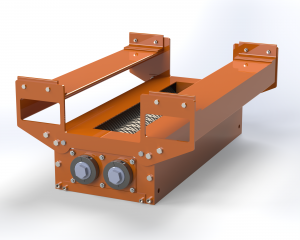

Crumbler® Processing Heads

Designed for optimal particle size reduction. Required for all Crumbler® rotary shear machines.

Related Items to Consider

Read more about our Crumbler® technology:

Application of Crumbler® Technology to Recovered Plastics and MSW for Chemical Recycling and Waste to Energy

Abstract Crumbler® rotary-shear technology from Forest Concepts is the solution to produce high quality feedstocks. This short presentation explains some of our emerging work in applying this patent-protected technology to recovered plastics and MSW for chemical recycling and waste to

Techno-Economic Analysis of Forest Concepts, LLC Crumbler® Operated at Proton Power to Process Crumbles® from Hardwood Chips

Abstract Developing cost-effective methods for processing biomass into an economic biofuel product is critical to the success for the bioenergy industry in the United States. Size reduction and drying of the material, where used, are two of the most costly

Production of corn stover feedstocks using rotary shear mill and screen system

Abstract Baled corn stover at 10% +/- moisture (wet-basis) was comminuted and sorted to obtain a particle size with a geometric mean diameter (Xgm) of 1.34 mm and particle size distribution to match the Idaho National Laboratory (INL) feedstock used

Woody Biomass Size Reduction with Selective Material Orientation

Abstract Roundwood logs from forests and energy plantations must be chipped, ground, or otherwise comminuted into small particles prior to conversion to solid or liquid biofuels. Results & discussion: Rotary veneer followed by cross-grain shearing is demonstrated to be a

Beneficiation of Chipped and Shredded Woody Biomass

Abstract Forest Concepts, with funding from USDA NIFA SBIR program, developed methods and equipment to reprocess low-value dirty forest chips, tree service chips, and hog fuel into high value clean wood fiber and other valuable fractions. Traditional clean sources of

Shear Processing of Wood Chips into Feedstock Particles

Abstract We have an objective to convert cellulosic biomass raw materials into small particles that are optimized for biochemical and/or thermochemical conversion to liquid transportation fuels. As a side effort, we are interested in producing feedstocks for composite bioproducts, solid