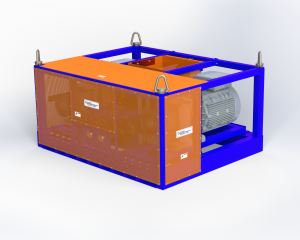

P24M Family of Crumbler® Machines

Our Production-Scale Rotary Shear

Our P24M family of machines have a small footprint but are strong enough to handle a wide range of materials including wood chips, corn stover, switchgrass, bamboo, sage, hemp, agave, and more. The machine is capable of processing up to 15 wet tons (7.5 dry tons) per hour and up to 105,000 wet tons (52,500 dry tons) per year* of your raw feedstocks into precision particles.

Key Features:

- Processes both high and low moisture feedstocks (no pre-drying required)

- Produces highly uniform particles to increase conversion efficiencies

- Low energy consumption

- 150hp standard (others available)

- PLC controls available

- Modular for easy system integration (e.g., single unit, stacked, sequential)

- Smooth, quiet operation

- 24″ wide infeed capacity

- Small footprint – only 7.2′ X 5.8′

- Standard power – 460VAC 3ph

- Multiple cutter-width processing heads available to tailor feedstocks for your process (standard widths are 1/4″, 3/16″, 1/8″, and 1/16″)

- Processing head sold separately

* Throughput estimates based on ideal feedstocks and a skilled crew. Stated throughput is for green wood chips into 1/4″ feedstock particles. Throughput is inversely proportional to comminution ratio and final particle size. Other configurations and versions with alternate capacities are feasible. Dust control may be needed depending on moisture content and processing conditions.

Two P24M Crumbler® modules can be stacked in a tower configuration to your specifications.

We are not limited to this design; please contact our engineering team for assistance.

Related Items to Consider

Email us to obtain a quote, discuss your project, or schedule a demonstration at our Auburn facility.