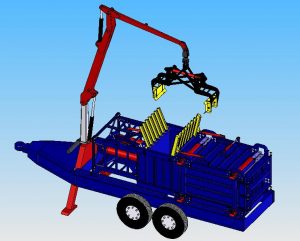

Bighorn® Biomass Baler

Reducing the Cost of Woody Biomass Collection

Forest Concepts has completed development of a mobile Biomass Baler as an alternative to chippers and grinders. After 10 years of development and testing, a complete family of models are ready for manufacture to-order.

- Minimize labor, noise & dust at worksites

- Cut transportation costs by using conventional flatbed trucks, trailers, or rail

- Improve safety over traditional chipping and grinding methods

- Handle woody biomass like any other baled urban recyclable

- Suitable for both small- and large-scale vegetation management and forestry operations

- Tow-behind balers can be direct replacements for urban chippers

- Grind bales at destination to optimal specs for end-use

The family of models include:

- 2510 – Entry model street legal baler (one bale per hour)

- 2515 – Entry model ag/off road chassis (one bale per hour)

- 2540 – Utility baler street legal (three bales per hour)

- 2540-C – Utility baler street legal (four bales per hour)

- 2545 – Utility baler ag/off road (three bales per hour)

Improving Powerline and Roadside Vegetation Management

Biomass balers are a particularly valuable addition to existing fleets of chippers for agencies and firms doing vegetation management. Collect the same material as a chipper but lower the cost of transportation with less dust, less noise, and fewer people on the ground.

Woody Biomass Is the Next Major Recyclable

Woody biomass from vegetation management projects is a valuable resource. Current methods for handling woody biomass include chippers and grinders, which can produce significant dust and noise. Unfortunately, these methods also render the biomass unusable for many potential uses.

Our mobile Bighorn® Biomass Baler technology allows woody biomass to be baled into large rectangular bales like agricultural crops. Even better, baled biomass can be aggregated and handled with the same logistics as recycled cardboard and paper bales. We offer street-legal balers suitable for urban collection as well as balers equipped to handle industrial-scale vegetation management and forestry operations.

The Brush You Collect Today Can Become Tomorrow’s Biofuel and Bioproducts

At Forest Concepts, we recognize that woody biomass is an unexploited source of bioenergy fuels and feedstock. Our baler enables cost-effective collection and delivery of cellulosic feedstocks to meet this growing demand.

Email us to obtain a quote, discuss your project, or schedule a demonstration at our Auburn facility.

Read more about our Baler technology:

Mode of Failure Model for Cutting Solid Section Biomass

Abstract Solid section biomass, such as wood and the node-zone of crop residues, has distinct modes of failure when loaded in cross grain shear. Shear bar design plays a part in determining what the failure mode will be at a

Biomass Baling into Large Square Bales for Efficient Transport, Storage, and Handling

Abstract Forest Concepts is working under a federal contract from the USDA CSREES SBIR program to develop better methods to collect and transport woody biomass collected from small-scale fuels reduction projects (ranging from residential lots to 20 acre parcels) in

Engineering Factors for Biomass Baler Design

Abstract Woody biomass is a core element of our nation’s strategy to replace imported oil and natural gas with renewable resources. The challenge facing potential biomass users, however, is how to economically recover and transport the material from residential neighborhoods,

Large Rectangular Bales for Woody Biomass

Abstract Woody biomass from wildfire prevention and forest health improvement projects is a significant source of feedstock for bio refineries, combustion energy facilities and other value-added uses. Baling into large rectangular bales offers increased bulk density and easier handling for