On April 27th, Forest Concepts received a contract continuation award of $608,774 to fund the third and final year of a $1,849,411 science and development project to reduce the risk of process upsets in biofuels and bioproducts manufacturing facilities. The project is being executed by our Forest Concepts Analytics team and will be completed by April 30, 2022. The development project is managed by the Bioenergy Technologies Office (BETO) within the Energy Efficiency and Renewable Energy (EERE) part of the U.S. Department of Energy.

The overarching objective of the proposed project is to contribute to the design and operation of reliable, cost effective, continuous flow and feeding of biomass feedstocks into a reactor of an integrated biorefinery. Poor flowability, high friction, and highly variable physical properties are facts of life with biomass feedstocks. Traditional metrics of compression ratio, Hausner Index, angle of repose, etc. give some indication of relative flowability among feedstocks, but provide little-to-no value for the engineering design of hoppers, chutes, feeders, and mixers. Many of the highly visible failures at advanced biofuels and bioproducts production facilities are due in-part to lack of useful and accurate engineering data for feedstocks. Where biomass mechanical properties data exists, it is not documented across realistic ranges of moisture and temperature. While the properties of minerals like gravel and sand are not affected by moisture and temperature, the mechanical properties of biomaterials such as wood chips and milled corn stover change significantly.

This project uses sound science and disciplined development to reduce the risk of similar failings in future biorefinery endeavors though the systematic analysis and development of robust feedstock handling modeling and simulation methods and tools. In partnership with sub-contractor Dr. Hojae Yi at the Pennsylvania State University we are adapting and improving known flowability simulation models for powders and minerals to the more difficult problem of biomass. At the end of the first two years of the project, we demonstrated animated simulations of biomass flow in hoppers, screw feeders, and rotary air locks.

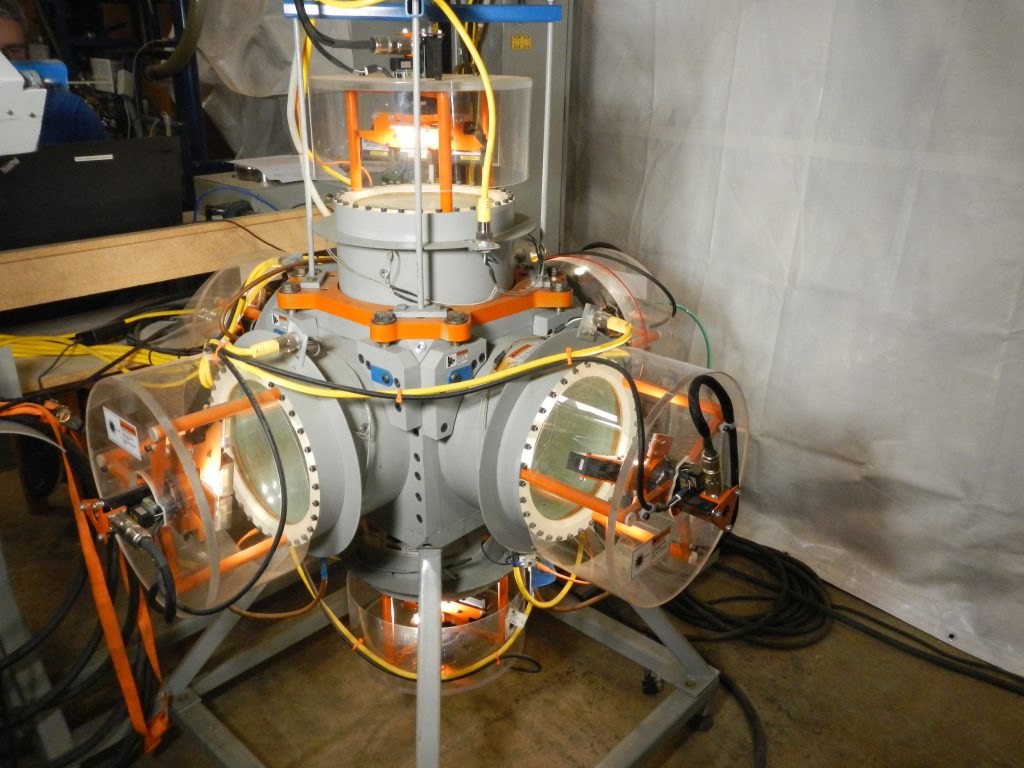

The parallel effort in the project is to design and improve laboratory protocols and equipment to generate the necessary engineering data for a full range of biomass feedstocks such as corn stover, wood chips, sawdust, etc. for use in flowability models and simulations. The first prototype is a true Cubical Triaxial Tester (CTT) that has a 250mm sample chamber. This novel test device produces mechanical properties of bulk biomass based on three-dimensional behavior. During the completed portions of the DOE project, more than 300 laboratory data sets have been completed using the new device, proving its performance, ease of use, and robustness.

During the final year of the project, using the new funds, Forest Concepts and Penn State will refine the laboratory methods and simulation models, test new materials and provide data sets to other DOE funded research teams, and publish a number of peer-review manuscripts.

The models and laboratory methods are now available for access by beta users in industry, at engineering firms, and laboratories. For additional information or to discuss access to our prototypes, please contact the Forest Concepts team.