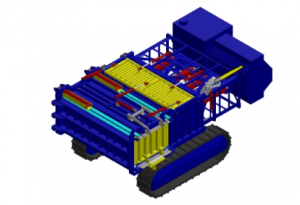

Bighorn® Biomass Baler

Reducing the Cost of Woody Biomass Collection

Forest Concepts has completed development of a mobile Biomass Baler as an alternative to chippers and grinders. After 10 years of development and testing, a complete family of models are ready for manufacture to-order.

- Minimize labor, noise & dust at worksites

- Cut transportation costs by using conventional flatbed trucks, trailers, or rail

- Improve safety over traditional chipping and grinding methods

- Handle woody biomass like any other baled urban recyclable

- Suitable for both small- and large-scale vegetation management and forestry operations

- Tow-behind balers can be direct replacements for urban chippers

- Grind bales at destination to optimal specs for end-use

The family of models include:

- 2510 – Entry model street legal baler (one bale per hour)

- 2515 – Entry model ag/off road chassis (one bale per hour)

- 2540 – Utility baler street legal (three bales per hour)

- 2540-C – Utility baler street legal (four bales per hour)

- 2545 – Utility baler ag/off road (three bales per hour)

Improving Powerline and Roadside Vegetation Management

Biomass balers are a particularly valuable addition to existing fleets of chippers for agencies and firms doing vegetation management. Collect the same material as a chipper but lower the cost of transportation with less dust, less noise, and fewer people on the ground.

Woody Biomass Is the Next Major Recyclable

Woody biomass from vegetation management projects is a valuable resource. Current methods for handling woody biomass include chippers and grinders, which can produce significant dust and noise. Unfortunately, these methods also render the biomass unusable for many potential uses.

Our mobile Bighorn® Biomass Baler technology allows woody biomass to be baled into large rectangular bales like agricultural crops. Even better, baled biomass can be aggregated and handled with the same logistics as recycled cardboard and paper bales. We offer street-legal balers suitable for urban collection as well as balers equipped to handle industrial-scale vegetation management and forestry operations.

The Brush You Collect Today Can Become Tomorrow’s Biofuel and Bioproducts

At Forest Concepts, we recognize that woody biomass is an unexploited source of bioenergy fuels and feedstock. Our baler enables cost-effective collection and delivery of cellulosic feedstocks to meet this growing demand.

Email us to obtain a quote, discuss your project, or schedule a demonstration at our Auburn facility.

Read more about our Baler technology:

Conceptual Specification of Forest Utility Balers for Woody Biomass

Abstract The forest utility modular woody biomass baler is designed to maximize recovery of forest residuals from small/remote/stranded landings, scattered roadside windrows and piles, thinnings from hand crews, and forest management prunings. The baler module is designed to be incorporated

Conceptual Specification of Large-Bale Forest Residuals Balers

Abstract The large-bale modular woody biomass baler is designed to maximize daily production while baling previously piled logging slash, forest residuals, thinnings from hand crews, and forest management prunings. The baler is intended to be supported by an excavator-type grapple

Conceptual Specification of Forest Residues Balers using the Appreciative Design Method

Abstract Baling of fine forest residuals such as tops, branches, and thinnings is expected to reduce the cost of collection, transport, and processing. Baling may enable economical access to currently stranded biomass resources that are inaccessible to large in-woods grinders

Design of a Forest Residue Baler – Specification of Bale Dimensions

Abstract Specification of bale dimensions, configuration, and density are among the first decision decisions to be made for the design of a new class of forest biomass balers. The engineering team at Forest Concepts updated earlier work on baling of

Square Bales of Woody Biomass for Improved Logistics

Abstract The majority of fuels reduction work is conducted by hand crews in the wild and urban interface and near in-forest recreation/administrative assets. Today, most of the biomass is either piled for burning at some future time or is dragged

Interfacing Forest Engineering with Bioenergy Production

Abstract Woody biomass from forestland, urban greenbelts, and residential areas has the potential to provide more than 150 million tons per year of cellulosic feedstocks for biorefineries, pellet fuels, and fermentation. Production sites range from urban lots to large wildland