Bighorn® Biomass Baler

Reducing the Cost of Woody Biomass Collection

Forest Concepts has completed development of a mobile Biomass Baler as an alternative to chippers and grinders. After 10 years of development and testing, a complete family of models are ready for manufacture to-order.

- Minimize labor, noise & dust at worksites

- Cut transportation costs by using conventional flatbed trucks, trailers, or rail

- Improve safety over traditional chipping and grinding methods

- Handle woody biomass like any other baled urban recyclable

- Suitable for both small- and large-scale vegetation management and forestry operations

- Tow-behind balers can be direct replacements for urban chippers

- Grind bales at destination to optimal specs for end-use

The family of models include:

- 2510 – Entry model street legal baler (one bale per hour)

- 2515 – Entry model ag/off road chassis (one bale per hour)

- 2540 – Utility baler street legal (three bales per hour)

- 2540-C – Utility baler street legal (four bales per hour)

- 2545 – Utility baler ag/off road (three bales per hour)

Improving Powerline and Roadside Vegetation Management

Biomass balers are a particularly valuable addition to existing fleets of chippers for agencies and firms doing vegetation management. Collect the same material as a chipper but lower the cost of transportation with less dust, less noise, and fewer people on the ground.

Woody Biomass Is the Next Major Recyclable

Woody biomass from vegetation management projects is a valuable resource. Current methods for handling woody biomass include chippers and grinders, which can produce significant dust and noise. Unfortunately, these methods also render the biomass unusable for many potential uses.

Our mobile Bighorn® Biomass Baler technology allows woody biomass to be baled into large rectangular bales like agricultural crops. Even better, baled biomass can be aggregated and handled with the same logistics as recycled cardboard and paper bales. We offer street-legal balers suitable for urban collection as well as balers equipped to handle industrial-scale vegetation management and forestry operations.

The Brush You Collect Today Can Become Tomorrow’s Biofuel and Bioproducts

At Forest Concepts, we recognize that woody biomass is an unexploited source of bioenergy fuels and feedstock. Our baler enables cost-effective collection and delivery of cellulosic feedstocks to meet this growing demand.

Email us to obtain a quote, discuss your project, or schedule a demonstration at our Auburn facility.

Read more about our Baler technology:

PG&E Pilot Evaluates Chipped Versus Baled Debris

AUBURN, WASHINGTON, UNITED STATES, April 29, 2022 — The electric utility industry magazine T&D World published a story on their pilot trial of baling vegetation management debris as an alternative to chipping. Read the story in T&D World.

Processing Powerline Vegetation Management Biomass for Use in Distributed-Scale Gasifiers

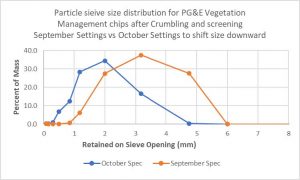

Pacific Gas and Electric (PG&E) sponsored a project to explore methods to gather powerline vegetation management woody biomass and process it into feedstocks optimized for delivery to distributed-scale gasifiers. A pilot study was conducted in Lake County, California where powerline trimmings were either chipped or baled, then ground at a central biomass processing facility, and finally milled / screened to achieve particle size distributions specified by a gasifier manufacturer. The vegetation included oak, pine, walnut, and other hardwoods. All materials were successfully processed into feedstocks.

Summary Report for Woody Biomass Baling Pilot Project

Abstract This project was the result of a proposal submitted by Forest Concepts, LLC to The Pacific Gas & Electric Company PG&E), through the PG&E / ADL Ventures ProblemSpace competition. The objective was to demonstrate baling as a lower cost

Baling & Roundwood Hauling for Fireline and WUI Fuels Reduction Woody Biomass

Abstract In this 17-slide Powerpoint presentation, Jim Dooley explores the challenges of on-site chipping of fireline debris and woody biomass and proposes Forest Concepts’ patent-protected baling technology as a solution. The presentation covers potential benefits such as labor and cost

Moisture Content of Baled Forest and Urban Woody Biomass During Long-Term Open Storage

Abstract This article describes how the moisture content of baled woody biomass varied during long-term open-air storage under conditions in the Pacific Northwest region of the United States. Large rectangular bales of forest and urban biomass were produced beginning in

Work Element Time Study of a Prototype for Baling Forest Residual Biomass into Large Rectangular Bales

Abstract The productivity of forest biomass collection equipment is highly dependent on site conditions, spatial distribution of biomass, operator skill, and functional design of the equipment used. A prototype woody biomass baler was used to produce large rectangular bales of