Abstract

The bioenergy industry is dependent on predictable and reliable feedstock handling equipment. High profile failures in the industry demonstrate the need for better modeling tools for feedstock handling, specifically tools which can model the bulk flow of biomass feedstock materials in handling equipment such as hoppers or screw conveyors. Measurement of bulk material flow characteristics is a critical component to inform modeling tools. Following examples in the soils and pharmaceuticals industries, a Cubical Triaxial Tester (CTT) was selected as a critical component to study relationships between applied stress on a bulk sample and the resulting strain on the bulk material.

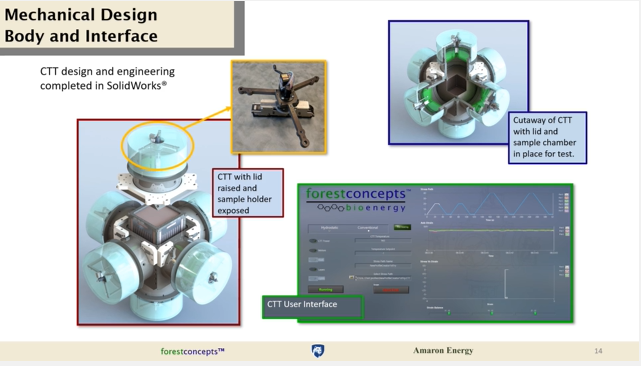

In cooperation with The Pennsylvania State University, Forest Concepts designed a CTT specifically to measure bulk biomass flowability characteristics. Several mechanical design constraints were identified to ensure proper scaling and repeatability. Major design constraints included sample chamber size versus particle length, volumetric strain sensing accuracy, independent axial pressure control, and sample chamber handling. This report explains how major design constraints were determined.

Below, please find links to both the published paper and a narrated presentation led by Forest Concepts engineer Chris Lanning.

About the Publication

C. J. Lanning, Yi, H., Dooley, J. H., Puri, V., and J.M. Whitt (2020). Written for presentation at the 2020 ASABE Annual International Meeting, July 12-15, 2020. Auburn, WA, Forest Concepts, LLC.

Read the full article in PDF format:

Watch the narrated presentation: