Custom Processing

Custom, optimized processing of your biomass to reactor-ready feedstocks

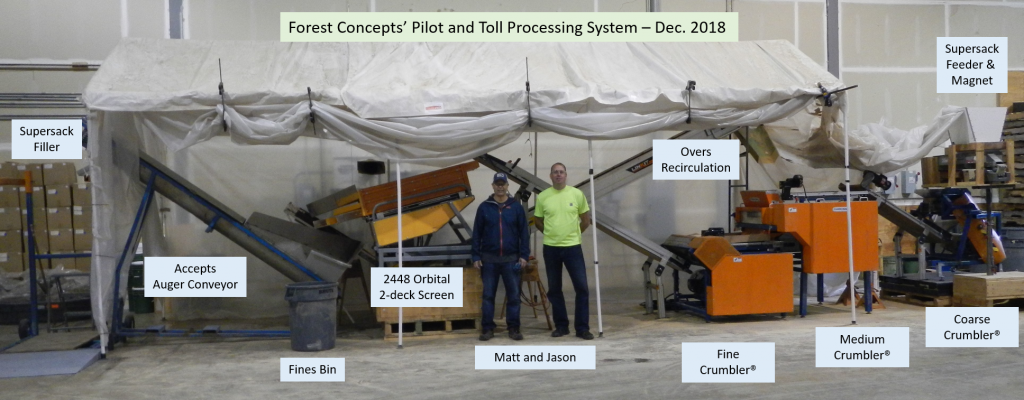

We built and operate a biomass feedstock processing facility that features our patented Crumbler® size reduction technology, proprietary orbital screening and advanced dryer. The Crumbler® rotary shear can produce a variety of sizes of uniform, flowable particles down to 1mm from high moisture biomass without drying when drying is harmful or before drying when dry feedstocks are required. Screening with our custom orbital two-deck screen enables sorting by particle length as well as cross-section and removal of client-defined fines when needed.

To date, we have been engaged by more than 40 laboratories, universities, and companies to develop and provide optimized feedstocks to contribute to the success of their projects. During a recent 18-month period, the company’s processing facility converted 6-8 tons per month of client-sourced wood chips into 1mm uniform, flowable feedstock particles for a successful pilot plant while losing minimal fines.

We are capable of processing a wide range of materials and are currently accepting custom processing projects. To get started, fill out and submit the short form at the bottom of this page.

Our Processing Facility and Capabilities

Our Equipment (Partial List)

- Crumbler® M06R-10e

- Crumbler® M24S-30e

- Crumbler® M24P-20e

- Crumbler® Vari-head

- Bliss Hammermill E-22115 TFA

- FCLLC 2448 orbital 2-deck screen (2)

- Norris Thermal Belt-o-Matic 123B Dryer

- Forest Concepts cabinet tray dryer

- Supersack filler

- Vibratory feeder with magnet

- Rapid moisture analyzer

- Gilson Ro-Tap 12-inch sieve system

- Bulk density measurement

- Veneer lathe – 54-inch blocks

- 3-cubic yard feed hopper

- Conveyors

- Dust control system

- Comminution energy data acquisition

Moisture Capability

- Oven dry to saturated

Particle Size Range

- 1mm to 20mm geometric mean size

Working with Forest Concepts' Processing Facility

Ready to get started? Start by filling out the short form at the bottom of this page or call us to discuss your needs, biomass resource, and timing.

Here are a few details about our process:

- Raw biomass or intermediates can be delivered to us in bins, Gaylord boxes, supersacks, or in bulk.

- Finished feedstocks are shipped back in palletized 5-10kg boxes, supersacks, bins, or bulk.

- We can source forest, urban, and agricultural biomass for you from almost anywhere in North America through our network of farmers, foresters, aggregators, and agents.

- Our production grows with you as you advance from beaker to lab, pilot, and early commercial scale.

- Our facility is often used to generate feedstock yield, LCA, and energy data necessary for business planning and facility design.

- Client staff are welcome to participate in processing their feedstocks for training purposes.

Need custom processing services? Tell us a little about your project.

All fields with an * are required. Thank you!